If you’ve been following the news around safety workwear, you’d know that the new EN ISO 20345:2022 standard has had another update this year. This updated standard has a transition period until the end of 2027, meaning you’ll see products on the market that are certified according to the EN ISO 20345:2011, the EN ISO 20345:2022 as well as the updated EN ISO 20345:2022 standard. Sounds a bit confusing? Not to worry! In this blog, we’ll go through some of the key changes in the latest update. Rest assured, all Black Hammer products certified this year have been tested according to the new EN ISO 20345:2022 standard.

Main Changes to the Standard

Perforation-Resistant Insert’s Puncture Resistance

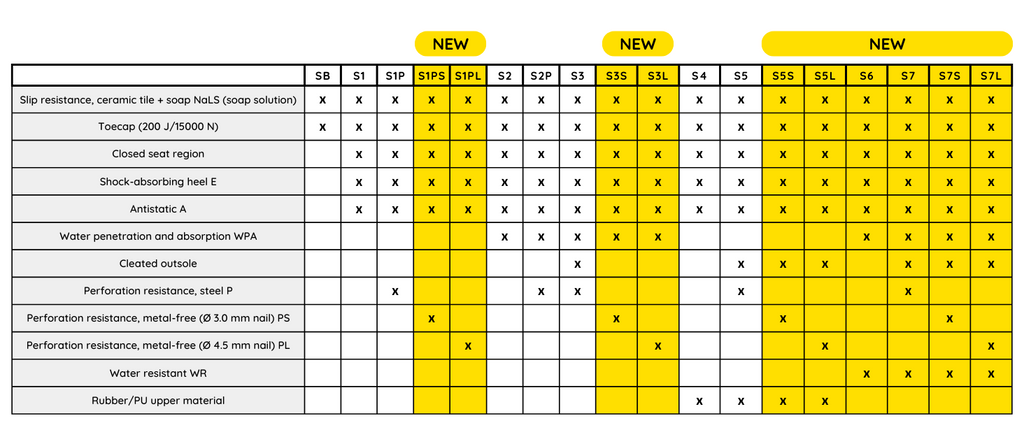

In the old standard, the perforation-resistant inserts or nail guards were marked with the symbol P. The tests were carried out with a 4.5 mm nail. In the new standard, the testing as well as protection classes for footwear having steel nail guards remain unchanged. However, for the non-metal perforation-resistant inserts, there is a change in markings and there are different protection classes based on the overall diameter of the nail test:

- PS markings for when the nail used in the test is Ø 3.0 mm (Small)

- PL markings for when the nail used in the test is Ø 4.5 mm (Large)

Therefore, the protection markings for the perforation-resistant inserts can now be S3S, S3L, S1P, S1PS and S1PL.

Slip Resistance

Slip resistance was marked as follows in the previous standard: SRA, SRB, and SRC.

In the new standard, however, the slip resistance does not have a separate letter symbol on the certificate, since it has now become a basic requirement. So, the test now is equivalent to the old SRA test that’s carried out on ceramic tiles coated with soap solution.

An additional feature of the new standard is a test carried out on ceramic tiles with glycerol solution. This is marked as SR (Slip Resistance) in the certificate. This additional feature is not obligatory. It is also important to note here that the slip resistance tests cannot be carried out on special boots or trainers, such as those with integrated studs. These are simply marked as Ø (Not Tested).

There is also a further resistance to fuel oil (FO) test that can now be carried out and marked. A lot of Black Hammer safety footwear already comply with this test.

Waterproof and Water Resistance

The previous standard marked the symbol WRU (Water Repellent Upper) for the water resistance of the upper material. According to the new standard, the upper material’s water resistance is marked with the WPA (Water Penetration and Absorption) symbol. The waterproof feature on the other hand, is marked with the WR (Water Resistance) symbol. Two new protection classes have also been introduced for waterproof footwear:

- S6 markings when the footwear meets class S2 requirements and is water resistant (WR)

- S7 markings when the footwear meets class S3 requirements and is water resistant (WR)

Additional Features

There are also some other additional features added to the new standard. These include:

- SC (Scuff Cap) - Abrasion resistance of the impact protection/toe cap. All of the materials used by Black Hammer for toe caps and impact protection meet this requirement.

- LG (Ladder Grip) - While testing this new feature is not mandatory, we are working on potentially adding this feature to the footwear.

Orthopaedic Safety Shoes

The latest update to the standard divides orthopaedic safety footwear into three types:

- Type 1 - Footwear having orthopaedic insoles fitted in them

- Type 2 - Safety shoes having an adapted outsole

- Type 3 - Safety shoes that are custom-made

The Updated Table According to the New Standard